An example of engraving on a block for magnets. There is no Z axis, the adjustment of the piercing depth is provided by focusing the lens. It is enough to select the b/w mode in the program or clean it yourself image – and as a result we get a contour template for cutting. They don’t indicate in the specifications, but from experience I’ll say that it engraves and cuts felt, foamiran, etc.

Well, a piece of foam. Preparing a template, for example, rose petals. Most of all I like its layout – a portal that can be moved, moved: there is no bottom. The metal itself is not engraved, not even scratched. Packaging — cardboard box, noname.  Good engraver low noise.

Good engraver low noise.

As a result, the picture 60×70, contour, was cut out for about an hour.

There is an interesting topic — three-dimensional foamiran applications.

Felt patterns are another example of choosing a mode for the material. Power: 2000 mW The edges are even. Model: 820100 Perhaps for some this will be the start of a business. Picture format : JPG / GIF / BMP / DIB / ICO / CUR /PNG Size: 15.2 x 16.3 x 14 cm I ordered it that week, from the presence in the MSC, they sent it on the same day, by courier (KSE), on the weekend they brought it right into my hands. Positioning Accuracy: 0.01mm

Specifications: An advantage of a laser engraver is that you can always run the program again, replicating the result. You can even take it with you. I took it in a state of cold mind and accurate calculation, since usually the price for them is $100. $120. One of the serious disadvantages is a rather long work, the laser in a straight line (strictly moving along the axes, without arches and arcs) stops at each pixel, and projects a beam for the set time (depth adj). Felt is cheap, cuts well, glues or stitches well. Black 2000mw Operating System: WIN-97/03/7/8/10 (Windows Vista / XP,Mac,Unix,Linux are not supported) If you bought a laser for the first time, install the driver, look for the program Laser engraving machine Colored and laminated surfaces are suitable for engraving – in this case only the top layer will be engraved. I will add about the engraving of cardboard, wood from the last review. They protect the axles from shock, they are not needed for work. The most difficult are white and transparent materials: it will be very difficult to engrave on a white sheet of paper or a transparent piece of acrylic. There are, of course, disadvantages, but with such a price you can compromise. Depending on the density of the material, its color and thickness, the effect may vary.

Let’s center the laser, start it. Next is a rose, glued from a thin sheet. Under the colors you can adjust the power, as a rule, light ones require more power / duration.

The sheet is quite thick, plus a rough template – you can see the pixels on the patterns.

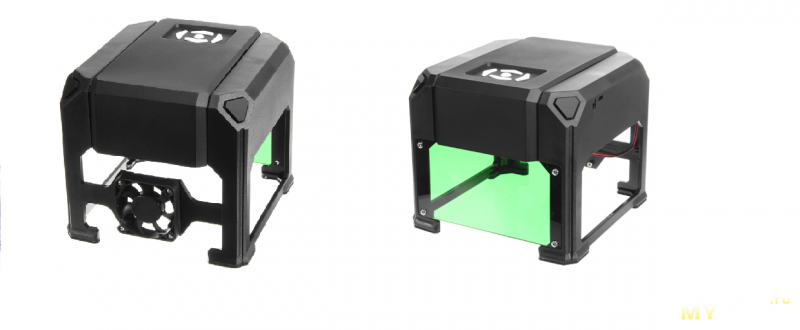

On the side panel there is a MicroUSB connector and a round jack (3.5mm) for power supply. Well, I just took it for cutting templates, stencils, etc. Inside 2 XY-axes of 4mm rails, travel about 80mm on each axis. We check the integrity of the kit after delivery, and immediately install the protective glass. You can focus a little "deep" – then "tough" will be thick sheets of foamiran / foam.

Suitable materials for engraving are: wood (including bamboo and wood-based materials such as MDF), paper, cardboard, leather, plastic, etc. Copy, connect, run the program. We unpack, check, look at the files on the USB flash drive. It’s better not to joke with the laser. Engraving height: No limit

Desktop Laser Engraver 2000mW USB 80x80mm

I bought at the beginning of the promotional hysteria on Ali, with the coupons of the seller and Alishka, about 4000 rubles came out, on the weekend they were already brought by courier (KSE), from the presence in the MSC.

And stencils, for example, for airbrushing/painting, for coffee, for drawing… Circles, etc. go for applications.

thin foaminan sheets Do not forget about airing the room.

As I said, the open layout allows you to install the laser engraver on large objects, for example https://tonaton.co.tz/s_279-waffle-irons, you can engrave on a cutting board for your beloved mother-in-law.

The kit contains the engraver itself, a power supply (5V/2A), a USB cable, a USB drive with drivers and sample pictures https://tonaton.co.tz/s_279-waffle-irons, test materials, a target for focusing, protective glass and fasteners, instructions.

Cutting time depends on exposure and size, felt thickness In general, this is a good opportunity to try something new, since the software is very simple, and the result – engraving on flash drives and cases – will be interesting.

Here’s what happened The depth of cut depends on the thickness and density of the material, on its type, on the color

surfaces (!). Well, and so on, it is best to first test the engraver on a surface sample and select the operating mode (shutter speed, focus). But it depends on the color, it is desirable to select for a specific type of material (type / thickness / color). If you choose a USB-jack adapter, you can power the laser engraver from the power bank If the felt is not https://jiji.com.gh/car-parts-and-accessories/nissan-juke homogeneous or “waves”, it may not cut through in places. Focusing the laser beam to a point (don’t forget about the target, be careful with the laser)

We remove the transport inserts in the running gear.

The laser engraver is very compact, it is a desktop option. Something will melt, and something will barely darken. There is no change in brightness, just the longer it is delayed, the stronger the burn.

I overdid it a little, cut through, even the edges were slightly charred. Actual not only for felt but also, for example, for coffee stencils. This laser engraver is quite an interesting and successful model. You can try with photoresist and PCB varnish.

There is no reflow. Actually, I did a promotion about this engraver, because the price was very good. Engraving range: 80*80mm Soot, too – cut, as if with a blade. In this way, you can apply a commemorative engraving on painted metal objects. An example of engraving on cardboard (meme from the Internet)

The power of the laser module allows not only engraving, but also cutting through some materials, which is suitable for making stencils, templates, patterns, etc.

For a long time I wanted to try to make patterns from felt and foamiran for soft toys and appliqués.

We take a template, any one (we draw it ourselves or look for it on the Internet)

Appliques and patterns are quite painstaking work, but cutting with scissors is even more difficult. In this way, you can make any templates from cardboard.

Clean up the excess, load it into the program